Product info

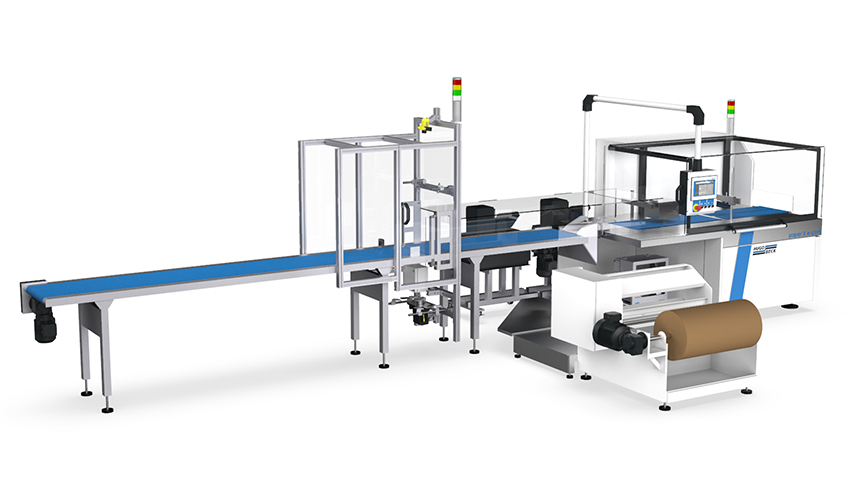

[ 1 ] paper X hybrid/paper X

CONTINUOUS FORM FILL AND SEAL MACHINE

FOR FILM AND PAPER PACKAGING

- ์ ํ ๋ช : paper X hybrid/paper X

- ์์ฐ์ง : HUGO BECK ( ๋ ์ผ )

- ์๋ด๋ฌธ์ : 031-790-4141~5

paper_X

paper_X_e-com

paper_X_hybrid

paper_X_hybrid_advance

์ฅ๋น์ฌ์

| TECHNICAL DATA | ย |

| Product infeed | manual as standalone/automatic in line |

| Product sizes | film: L: from 45 mm, W: max. 450 mm, H: max. 80 mm paper: L: from 100 mm, W: max. 330 mm, H: max. 50 mm/only for paper X E-Com max. 100 mm |

| Capacity | approx. 600 cycles/h |

| Paper | uncoated and coated of approx. 80 g/m2 to 130 g/m2 |

| Packaging style | two sides sewn, top overlap glued |

์ฅ๋น์ค๋ช

Film or paper? Stay flexible! The paper X hybrid is designed for packaging goods in paper or

film. A simple changeover ensures you are ready for the new product and the new packaging

material.

Whether using a chain infeed or infeed conveyor, the machines stand apart through their

continuous packaging process โ without stop-and-go โ maximising efficiencies by ensuring

there is no downtime when sealing or glueing.

Different machine versions are available, depending on how flexible you need to be:

โข the basic model paper X features paper packaging with overlap on top

โข the paper X E-Com features paper packaging with overlap on top for different product lengths

โข the paper X hybrid features paper and film packaging with overlap on top

โข the paper X hybrid advance features paper and film packaging with overlap on top

ย and side seal

์ฅ๋นํน์ฑ

โข One single machine for different packaging materials and types

โข Quick changeover in approx. 30 to 60 minutes between paper and film

โข Extremely high flexibility, future-proofing your packaging requirements

โข Easy line integration and connectivity with higher-level systems, Industry 4.0 Ready

โข Optional monitoring, analysis and visualisation of machine and operating data via

ย the Hugo Beck Cockpit