Product info

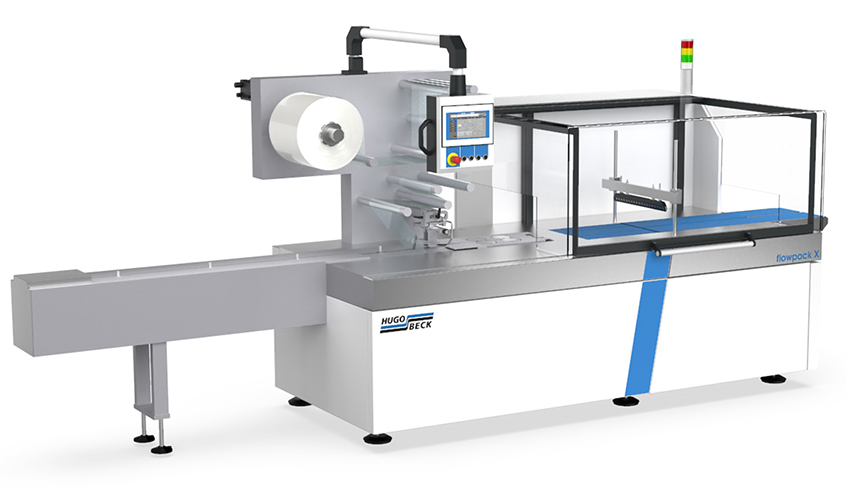

[ 2 ] flowpack X

CONTINUOUS FLOW PACK MACHINE

THE COMPACT SOLUTION FOR HIGH-SPEED PACKAGING

- ์ ํ ๋ช : flowpack X

- ์์ฐ์ง : HUGO BECK ( ๋ ์ผ )

- ์๋ด๋ฌธ์ : 031-790-4141~5

flowpack_X_chain_film_above_sealing_above

flowpack_X_chain_film_below_sealing_above

flowpack_X_chain_sealing_below

์ฅ๋น์ฌ์

| TECHNICAL DATA | ย |

| Product infeed | manual as standalone/automatic in line |

| Film/Paper | PP, composite films, biofilms, PE-coated paper |

| Product size | L: from 45 mm, W: 10 โ 450 mm, H: max. 200 mm |

| Capacity | up to 12.000 cycles/h |

| Versions | longitudinal sealing above or below |

์ฅ๋น์ค๋ช

The flowpack machine flowpack X achieves one hundred percent air-tight packaging seams,

seamless traceability and reproducible results from the very first product packaging. Packaging

under modified atmosphere is possible.

The flowpack X is available in two versions: with longitudinal sealing above or below.

Both versions can be equipped on a modular and individual basis. Examples here are finger

conveyor chains or infeed belts, thermal transfer printer, labelling machine and film roll changer

for continuous film unwind, i.e. non-stop operation.

Our flowpack machines are also available as hygienically designed version.

์ฅ๋นํน์ฑ

โข Air-tight packaging seams thanks to continuous transversal sealing

โข Customised design of fin seal for excellent product packaging stability and appearance

โข Optimum film feed for processing the most diverse of film types and grades

โข Siemens TIA Portal and free remote service

โข Smart user guidance via CoPilot and touch screen

โข Maximum serviceability and maintainability thanks to perfect access and numerous

ย maintenance-free components

โข Easy line integration and connectivity with higher-level systems, Industry 4.0 Ready

โข Optional monitoring, analysis and visualisation of machine and operating data via the Hugo

ย Beck Cockpit