Product info

ํด๊ณ ๋ฒก ํ์ฌ์๊ฐ

your partner for film and paper packaging machines

HUGO BECK 1955 โ 2021

1955 – Hugo Beck sets up his own mechanical workshop.

SPK 25 shrink packaging machines โ first series machine for the bakery sector.

Family owned, high range of machines in the film and paper packaging field for all kind of applications and speeds up to 18.000 cycles/hour.

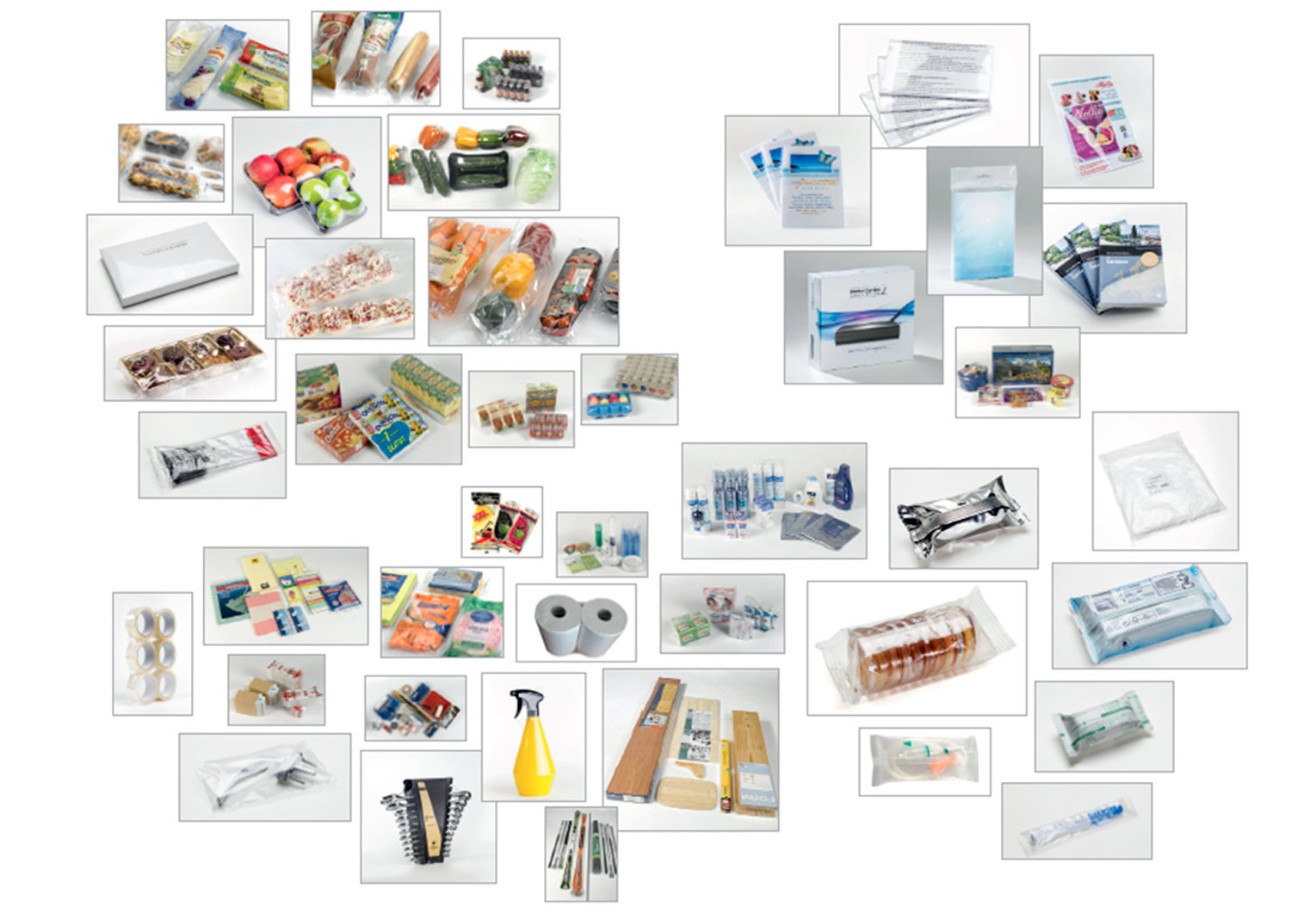

Applications

| Hugo Beck is the company with the most comprehensive manufacturing product range in the film packaging segment for flowpacks, poly bags, shrink and paper packs. | |

|  |

Figures

|

|

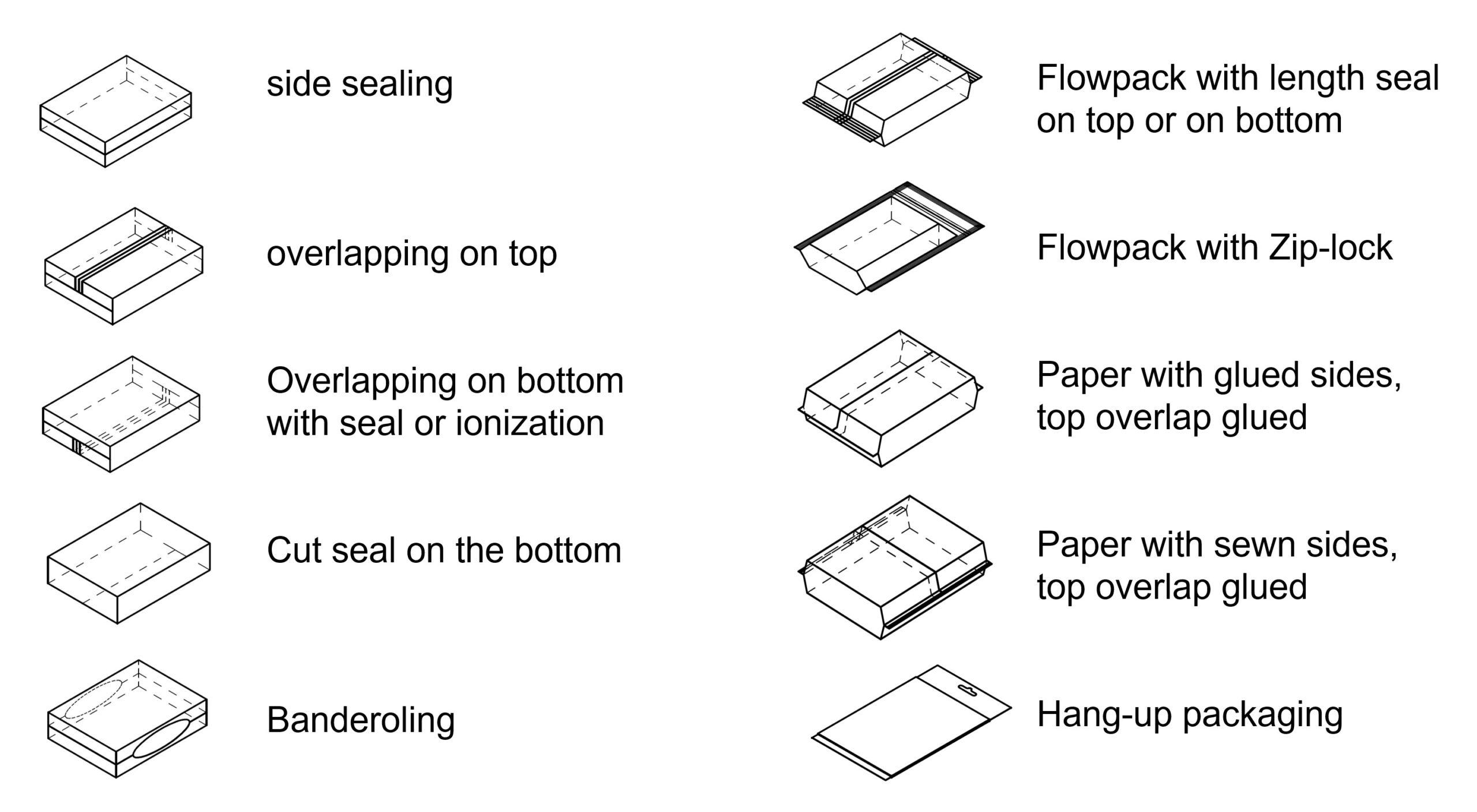

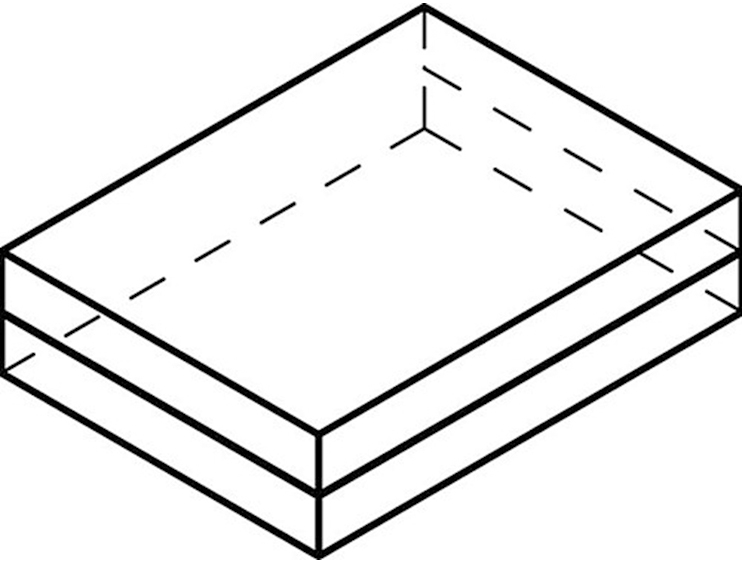

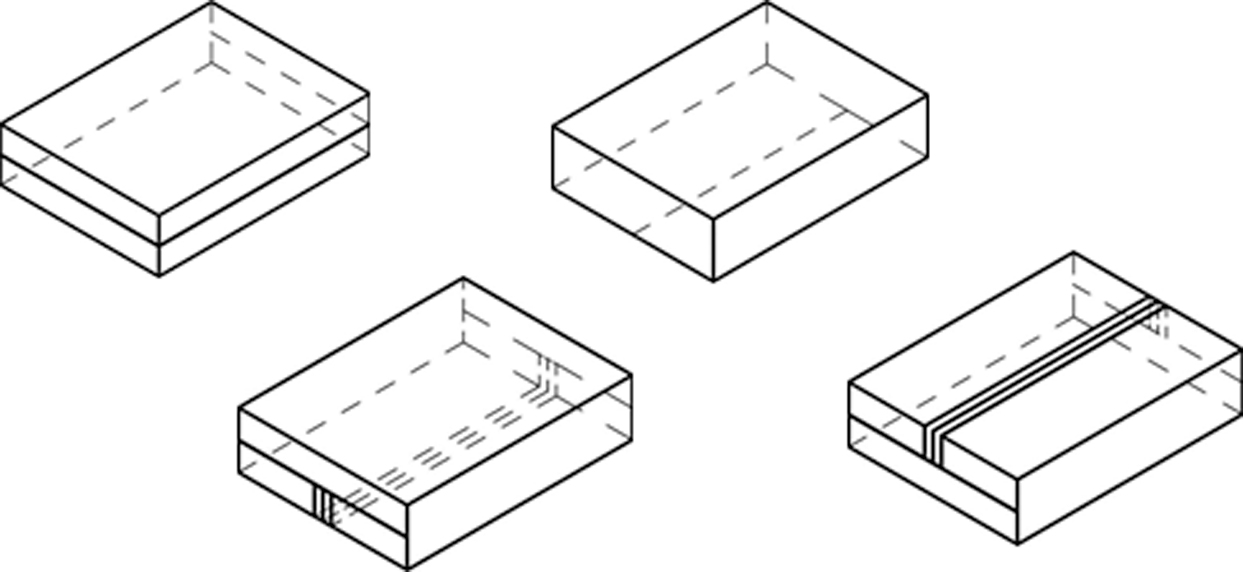

Packaging styles

|

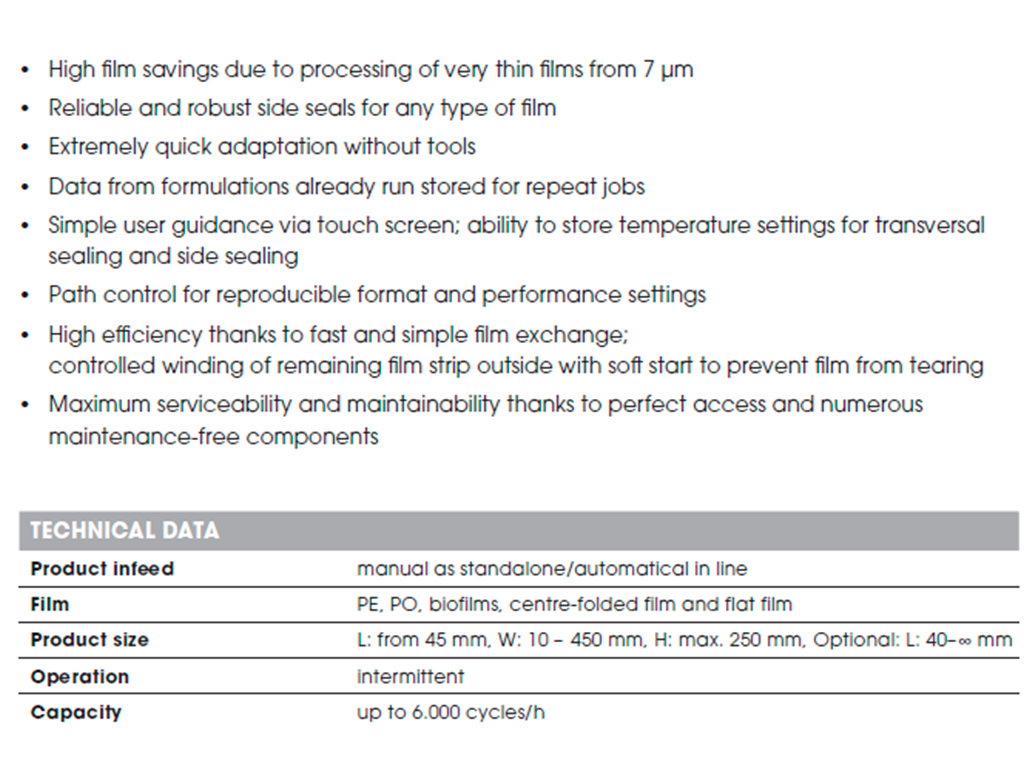

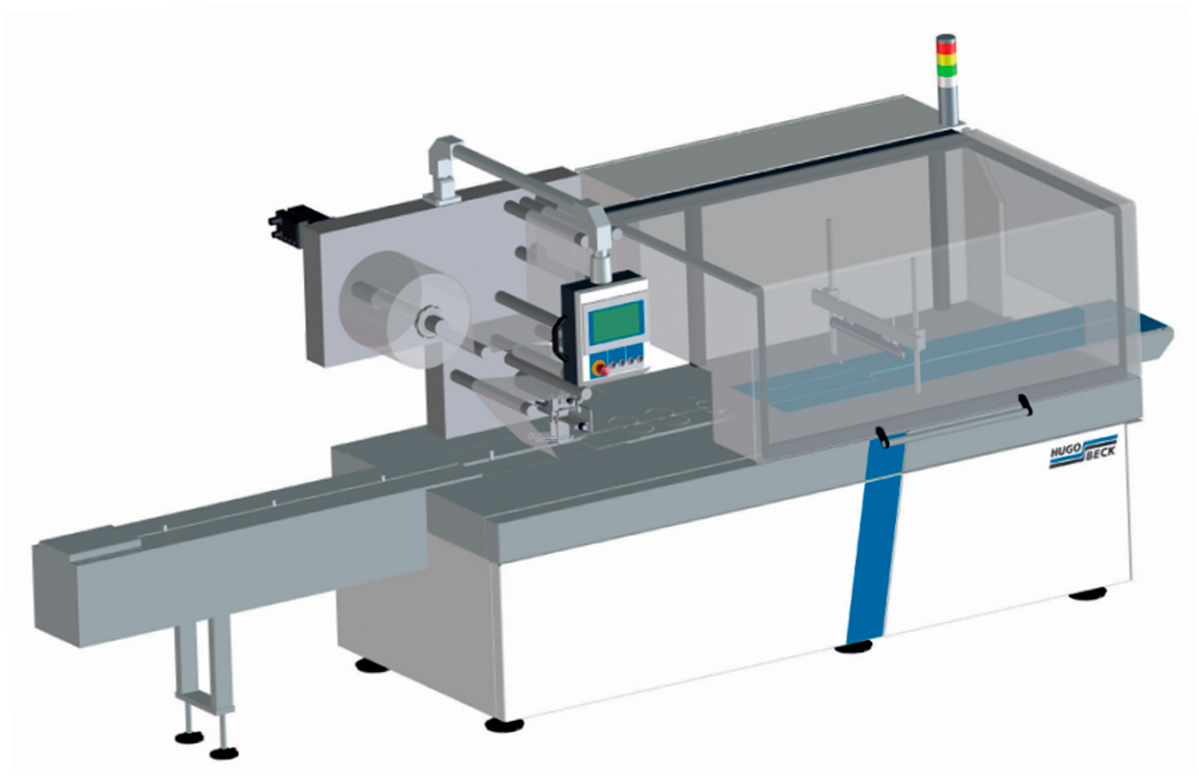

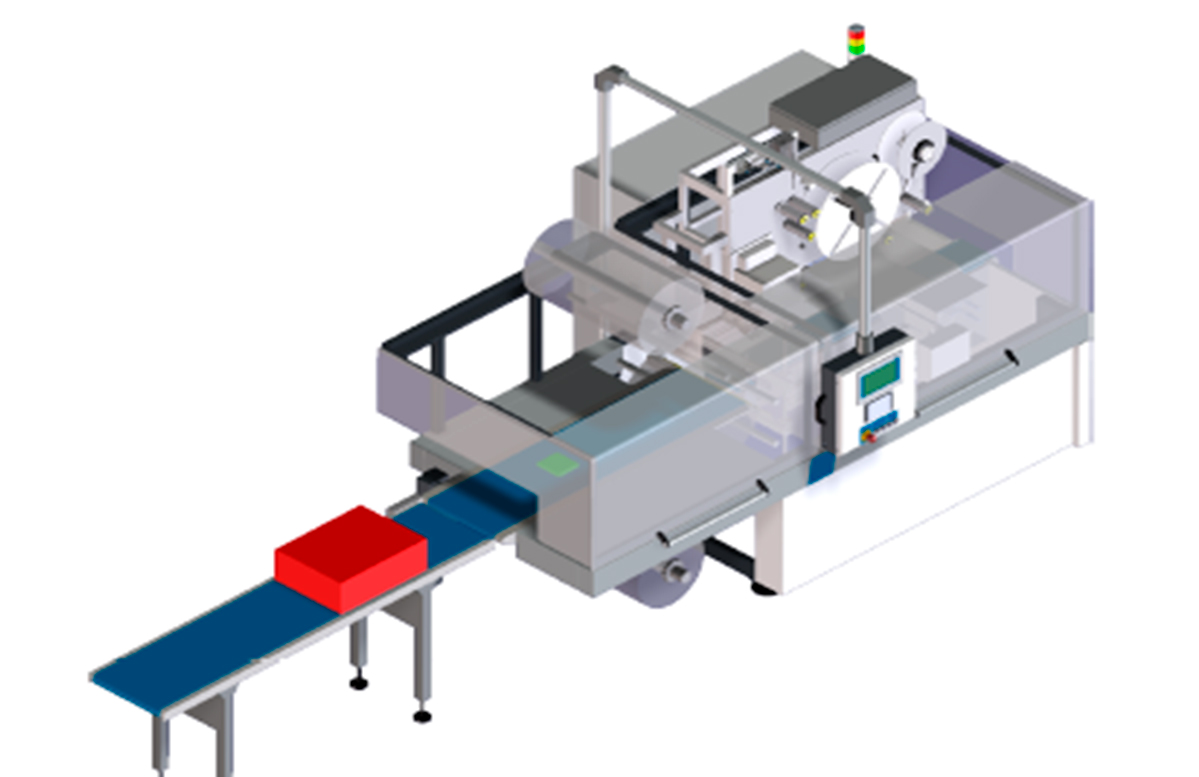

Packaging machine - FLEXO 500

ย

|  |

|  |

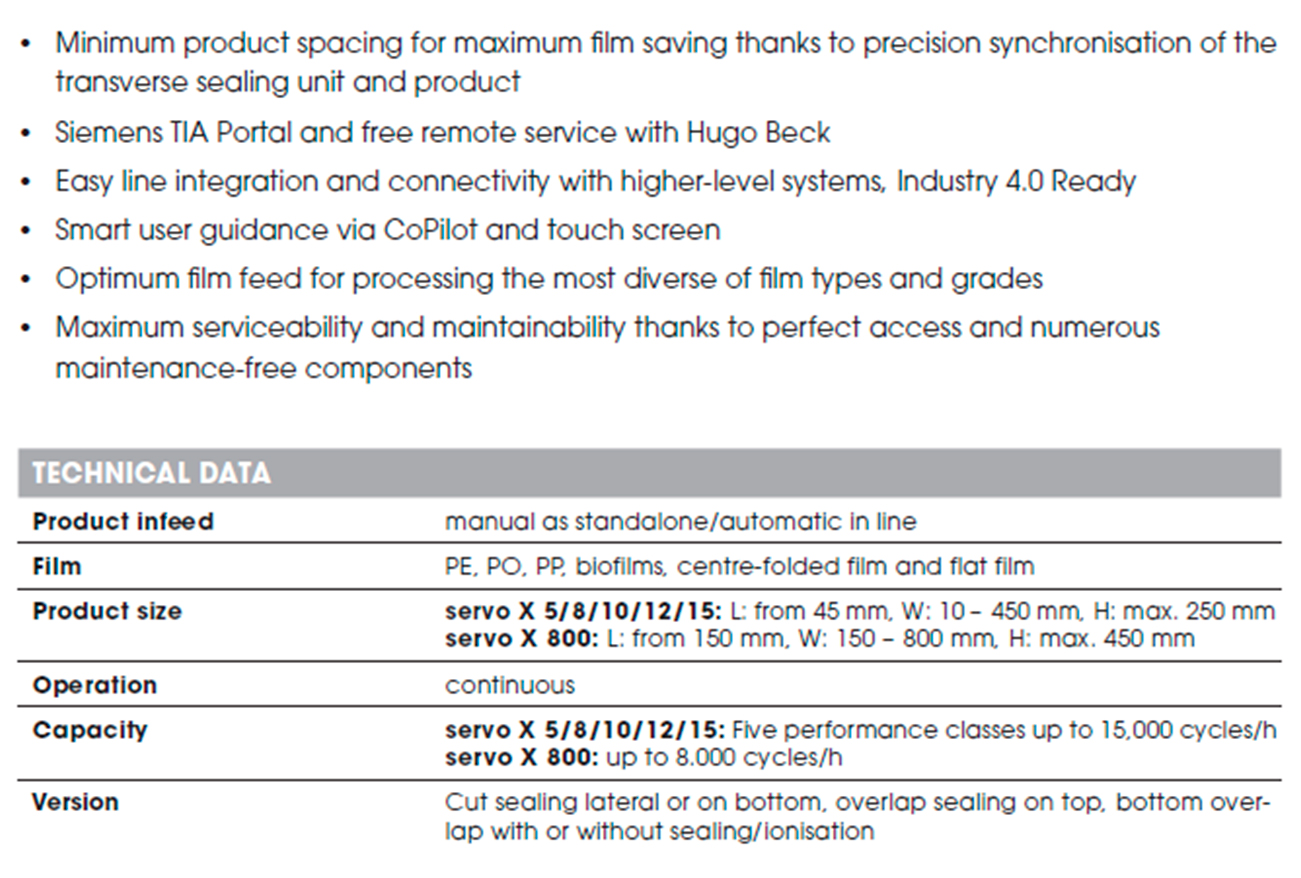

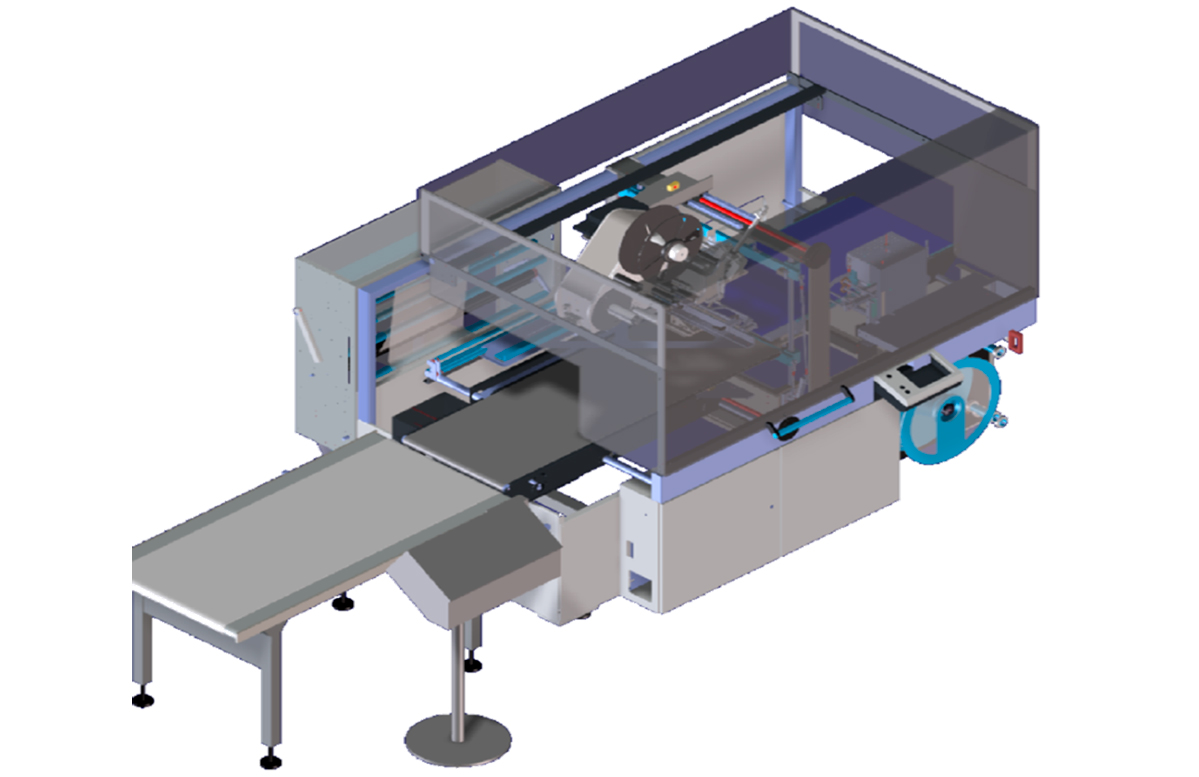

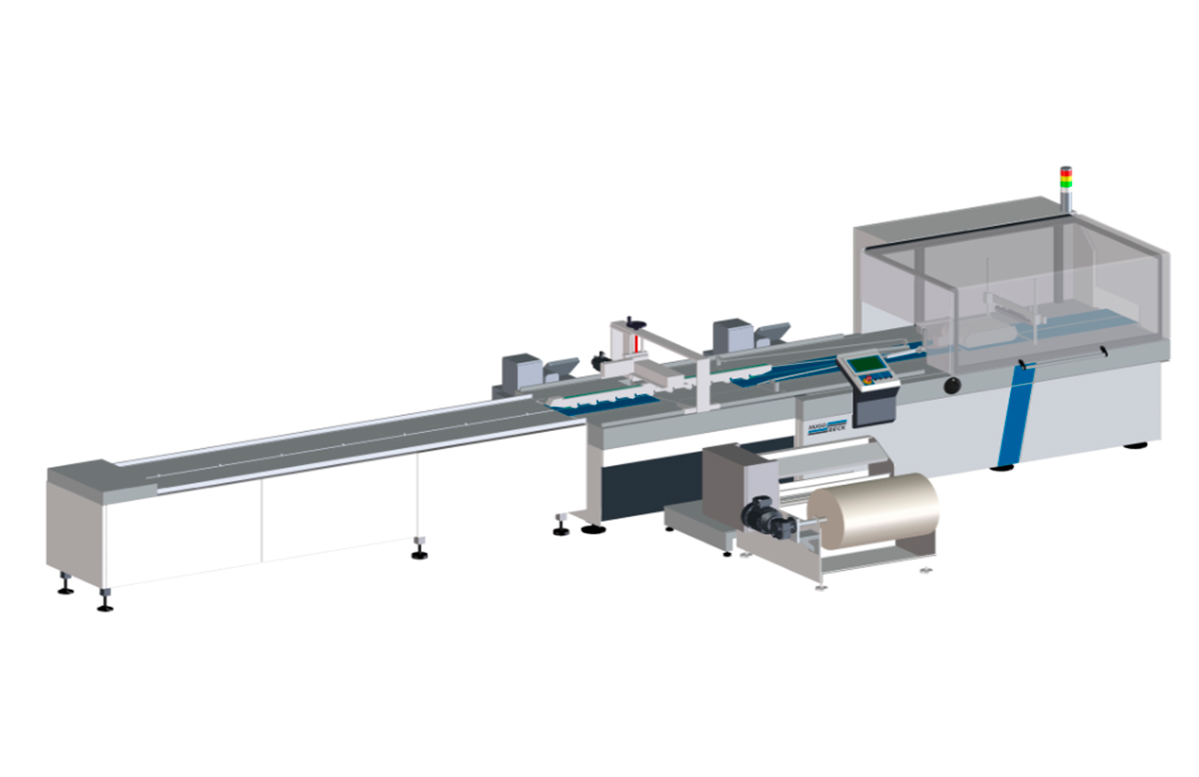

Packaging machine - SERVO X

|  |

|  |

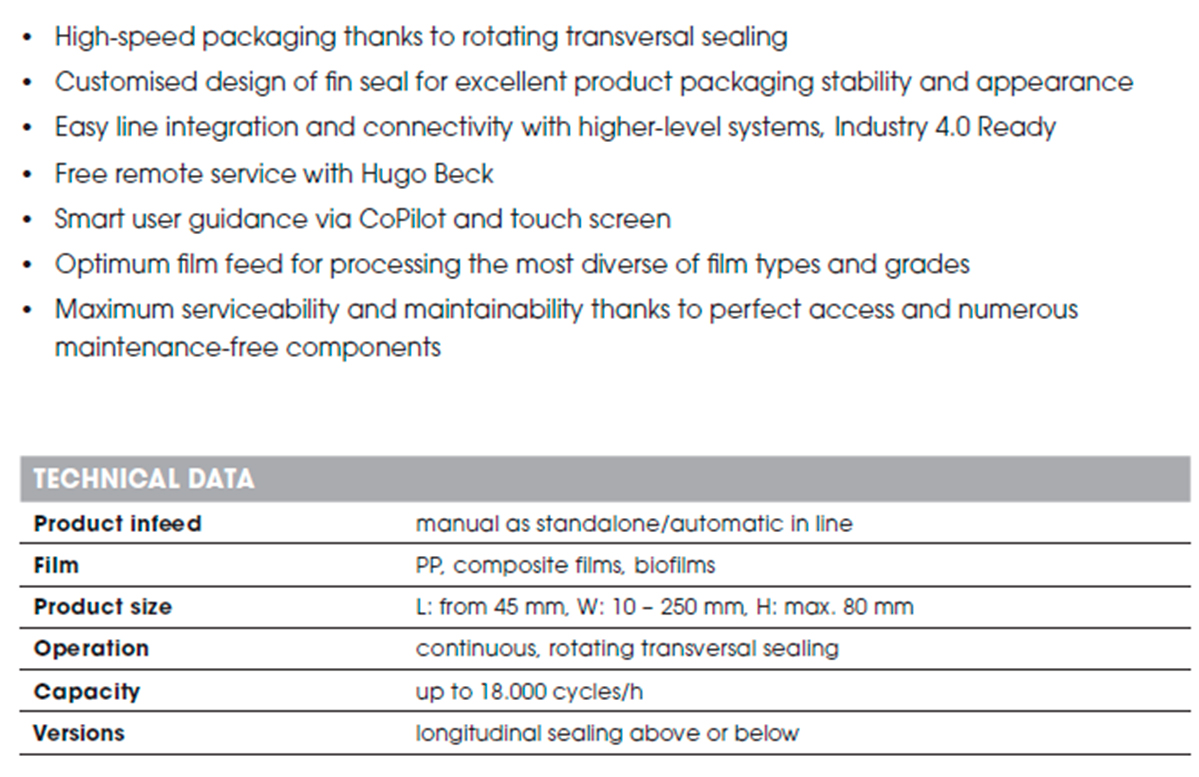

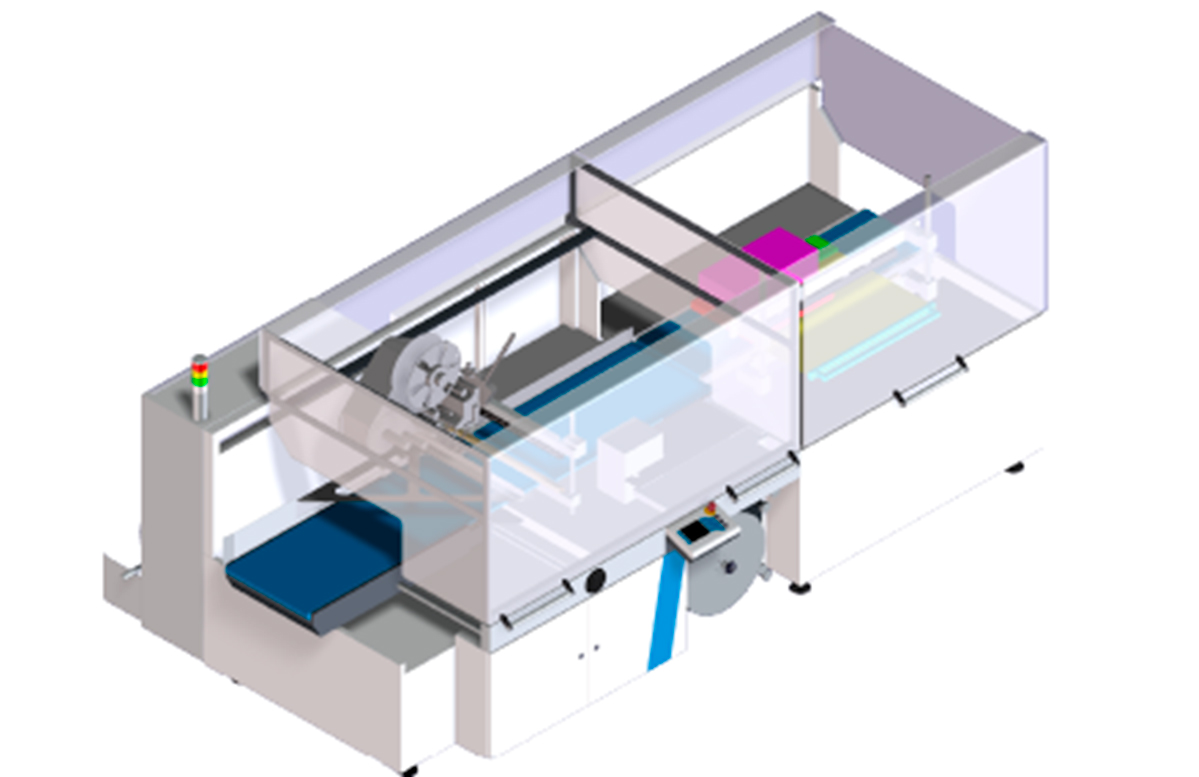

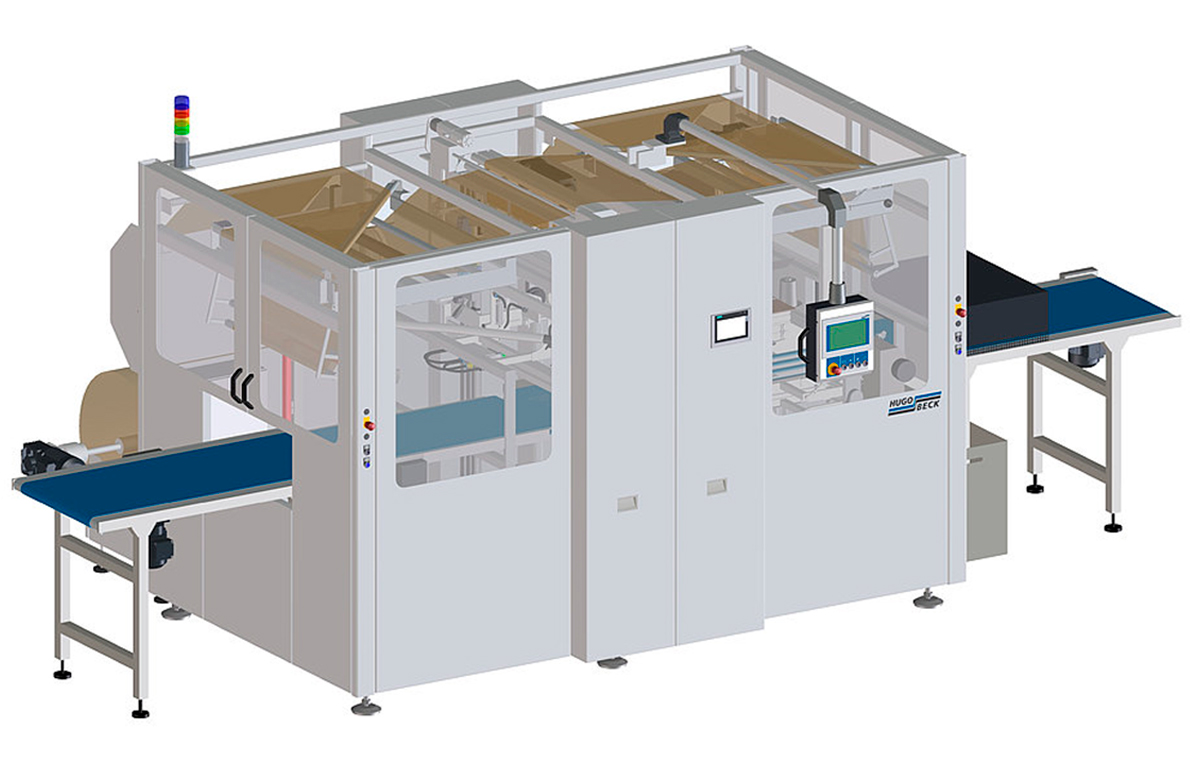

Packaging machine โ FLOWPACK

|  |

|  |

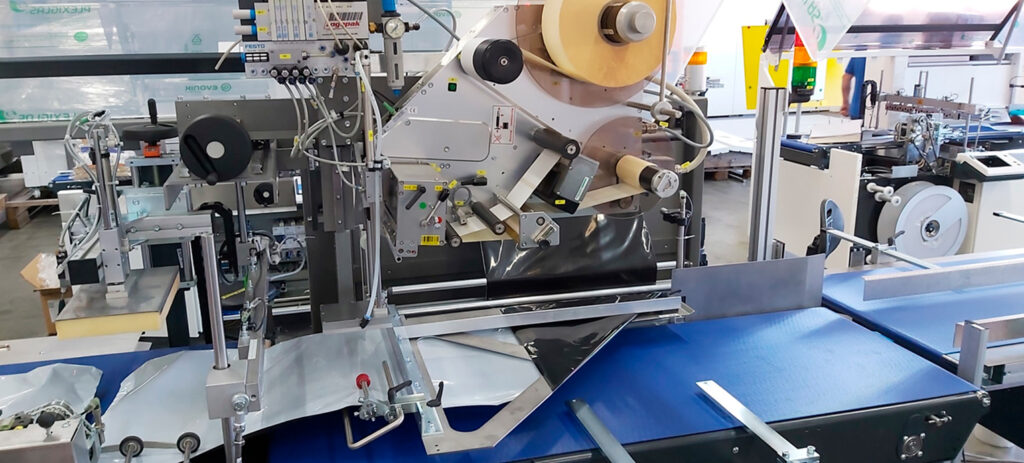

New e-com packaging solutions with film and paper

FILM solutions for the e-commerce market

version 1 features:

|  |

version 2 special features:

|  |

version 3 features:

ย |  |

version 4 special features:

ย |  |

PAPER solutions for the e-commerce market

| version 5 paper X e-comfeatures:

ย |   |

version 6 features:

– Lengthways sewn on both sides – Glued in the middle and lengthways on both sides

ย |   |

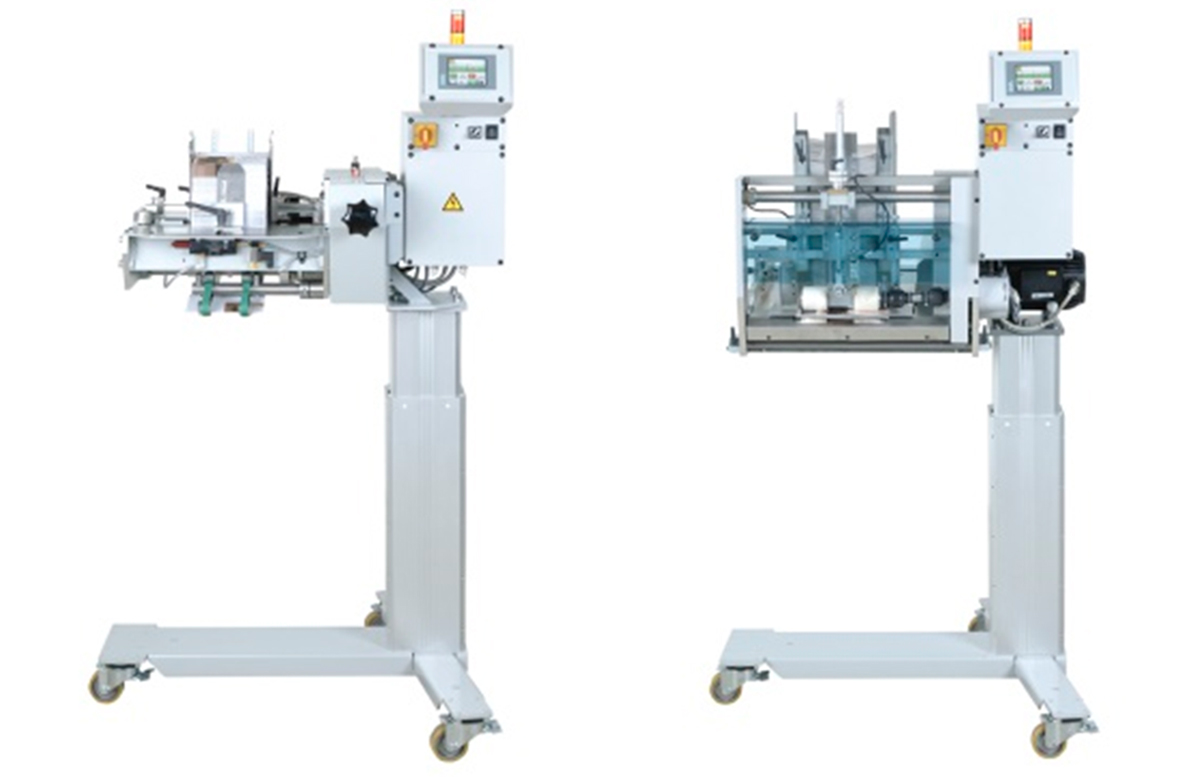

Automatization, robots and feeder systems

|   |

Customer Service / After Sales

|

|

|

|

Reference customers